![]()

STORAGE & ORGANIZATION | ACCESS & SAFETY | UTILITY PANELS | DECONTAMINATION

TEMPERATURE CONTROL UNITS

Modern Mechanical Fab, Inc. specializes in the fabrication of custom temperature control units. These skid mounted units incorporate all necessary components for fluid heating and cooling, chilled water and condensate recovery, air removal and system monitoring. We can build units capable of processing virtually any process fluid, at virtually any flow rate or temperature. Units may use plant supplied steam, hot water and chilled water, or skid mounted heaters and chillers for heating and cooling. Each unit is designed specifically to meet each customer's needs. Controls may be skid mounted and self contained, or can be interfaced with the customer's existing control system.

Heating / Cooling Combination Units

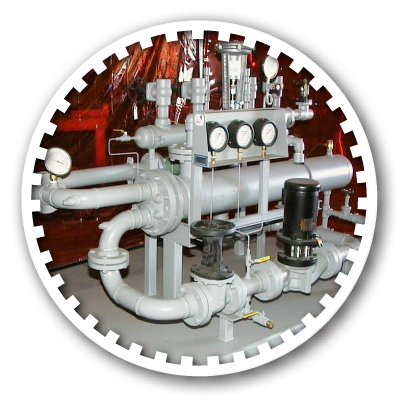

This is an example of a heating cooling unit. This skid incorporates a heating exchanger and a cooling exchanger. Hot and cold fluids are mixed together with a 3 way valve to maintain the required temperature. Heat is provided by plant steam, cooling is from plant chilled water. This unit was designed to control temperature for jacket water of a process tank.

Single Process Units (Heating Or Cooling)

Single Process Units (Heating Or Cooling)

This is an example of a heating unit. This skid incorporates a heating exchanger. Heat is provided by plant steam. This particular unit was designed to control temperature for propylene glycol used in an air handler heating coil for a powder processing room.

Multiple Process Units

This is an example of a heating cooling unit for 3 simultaneous processes. This skid incorporates all of the components of the combination unit.. Three separate systems are incorporated on one skid unit to minimize floor space This unit was designed to control temperature for jacket water of three separate tanks used simultaneously in a batch production process.

Portable Units

This is a small portable heating / cooling unit. The heat source for this unit is an electric heating unit. Cooling water is supplied by the plant's chilled water system. This unit was designed to be used in a hazardous environment, all electrical components are sealed and explosion proof.

General Specifications

General Specifications

Our temperature control units provide all the necessary components for controlling the temperature of process fluids in one self-contained frame mounted system. Heating, cooling, pumping, air separation, pressure management, temperature control and condensate recovery components are all included in the package. These units are custom designed for each customer's application. We offer units to suit virtually any fluid, flow and temperature requirements. We will size heat exchangers, control valves, pumps, condensate recovery components, and piping to meet the customer's needs.

System Components

We can build systems utilizing virtually any manufacturer's components. We work with Bell & Gossett, Taco, and Spirax / Sarco components most commonly. We can just as easily build units with any other manufacturer's equipment to suit our customer's preferences.

Construction

Construction

Frames are constructed of structural steel tube and plate. All structural frame joints are continuous welded by qualified welders. All piping components are supported by the frame. Holes are provided in the base for leveling and floor attachment. All piping components are sized for the specific application. We will observe any industry or plant specific requirements as outlined by the customer. All fabrication is done in strict accordance with the pipe and electrical trades standards.

Instrumentation & Control

Temperature and pressure gauges are provided to monitor the system as needed. Gauges are mounted in a stainless steel panel located for easy access. We can provide a skid mounted programmable logic control for system monitoring and control, or provide the necessary mechanical and electrical interface components to tie into the customer's control systems. All carbon steel units are completely painted after assembly and testing. Our standard finish is Sherwin Williams epoxy paint. Our standard colors are gray and safety blue. We can provide other colors upon request. Stainless Steel or Aluminum framed units may be painted, or left unpainted, based on customer preference.

Serviceability

All major components are removable for service. Unions and flanged connections are provided to allow removal where needed. Valves are provided for isolation of components during service. Piping layouts are designed to allow non essential components to be isolated without system shutdown. All system connection points are located at the outside of the unit for ease of installation.

Documentation

We will provide dimensional drawings and owner's manuals for all units. A preliminary drawing will be provided for customer approval, and as-built drawings will be provided at delivery. We can provide CAD files upon request.